Elevator Gearbox

I designed this gearbox as a part of a three-person team for our third year machine design final project. I was responsible for the preliminary force calculations, the shaft design review, the bearing selection and the enclosure design.

Problem Definition

Objectives:

- Input Power: 10 kW

- Input Speed: 1200 rpm

- Input Type: Electric Motor

- Output Speed: 200 rpm

- Use: Elevator for people

Goals:

Force Calculation

I created this spreadsheet to allow for easy iterations of calculations. These numbers applied to the entire gearbox and would dictate the design of individual components. Fixed values were derived both from project specifications, and research on existing gearbox and elevator loads and safety factors.

Gears

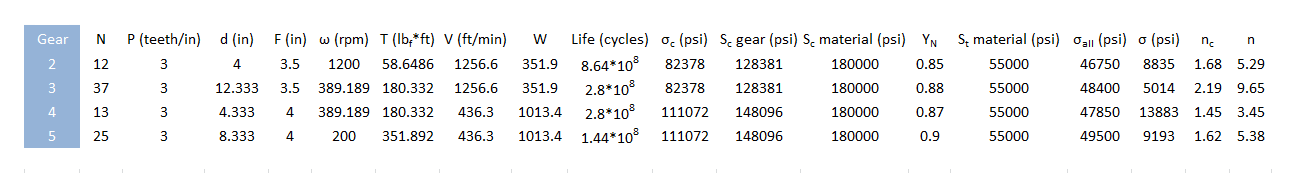

This table contains the results of the gear calculations. They were performed and checked by my teammates Eric Edwards and Adam Desjardins respectively. The rest of the components of the gearbox were designed to accommodate the gears, and therefore there were no iterations in this step.

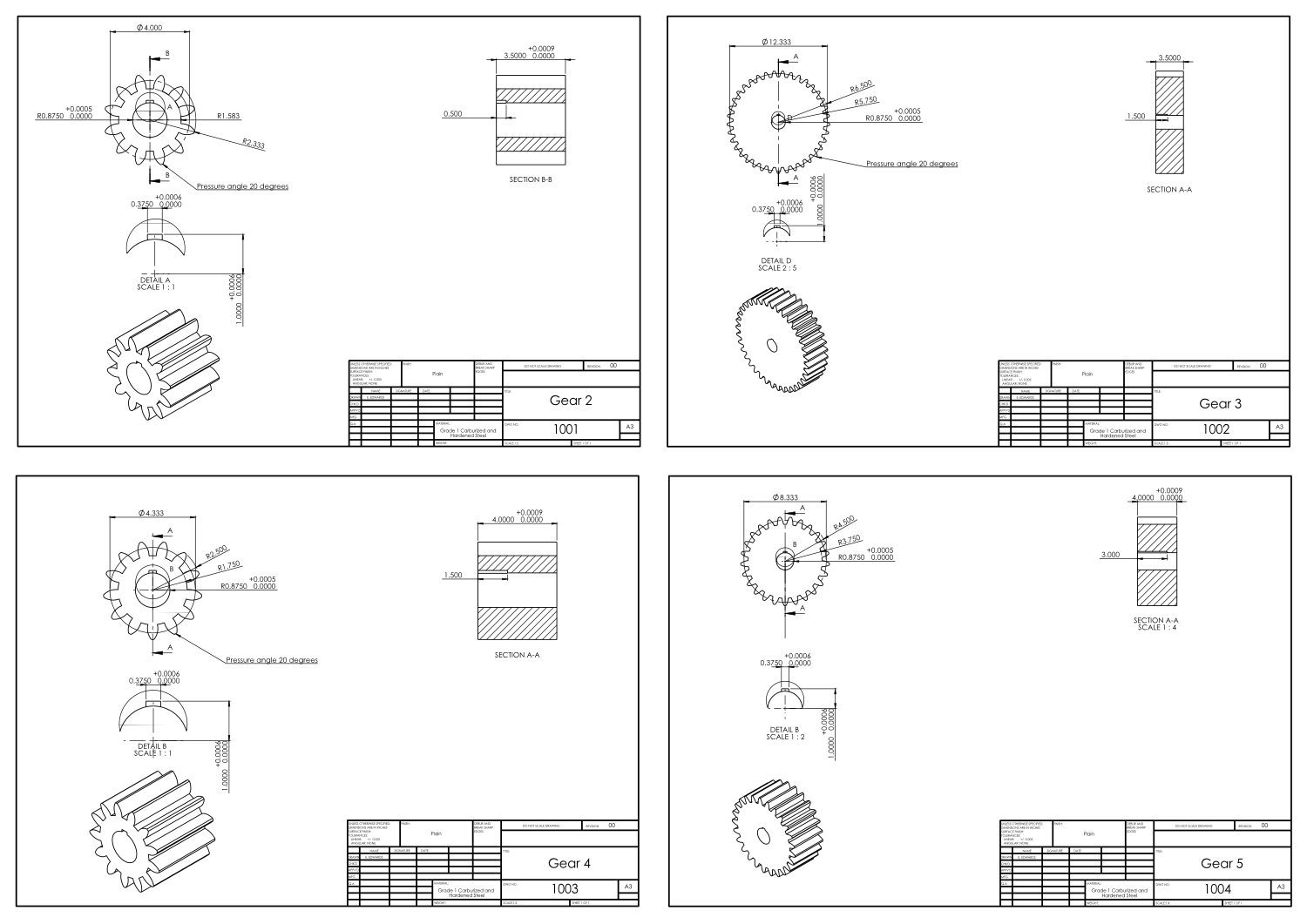

Gear drawings

Shaft

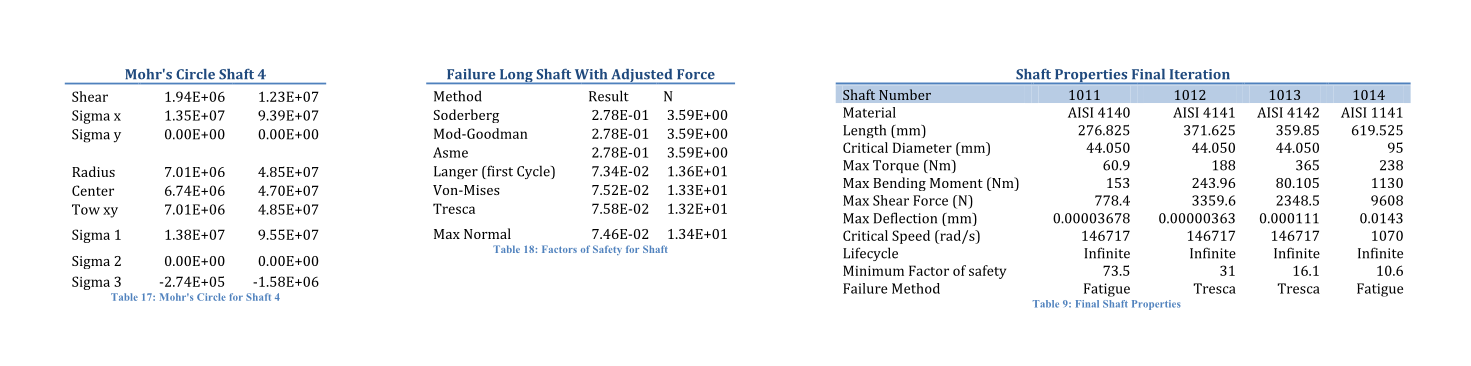

Above are two tables summarizing sample stress calculations on the shafts, and a table containing final shaft specifications. They were performed by my teammate Adam Desjardins and checked by myself. Multiple iterations with various materials and dimensions were needed before a successful design solution was found. Bearing selections were performed in parallel and often informed shaft design iterations. Shaft keyways have 1.5mm corner radii for milling.

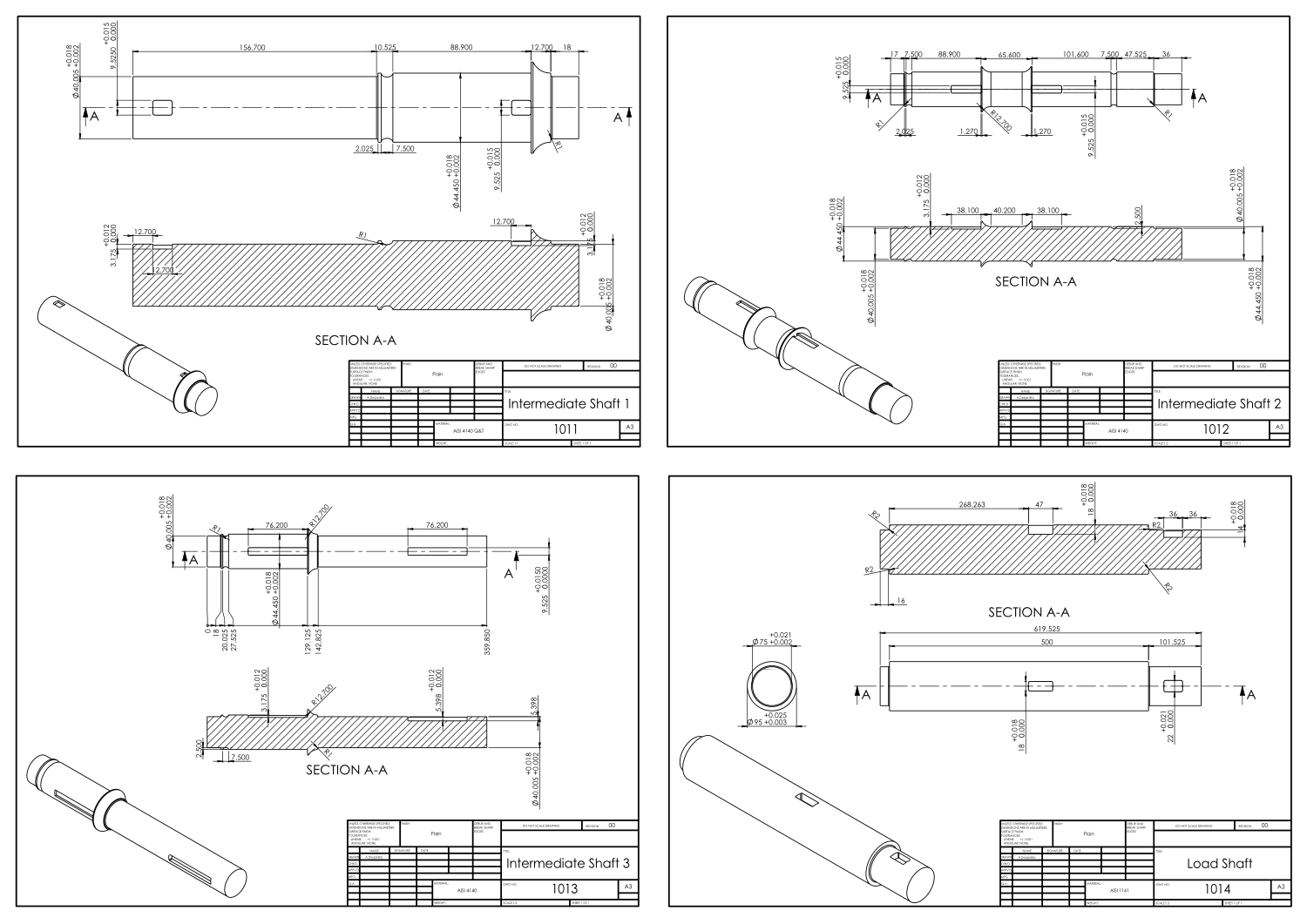

Shaft drawings

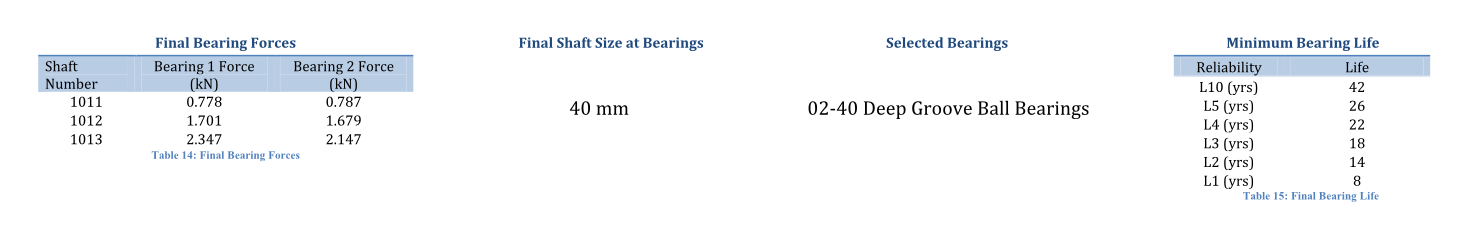

Bearings

These tables summarize my calculations on the bearing selection. The bearings needed to be doubled up in one location because the force was too large. Although the calculation was relatively simple, I had to be highly involved in the shaft design to ensure that the forces applied by the shaft and the shaft diameter would allow the required bearing life. The required life (20 years) was met with 96% reliability. Calculations were checked by my teammate Eric Edwards.

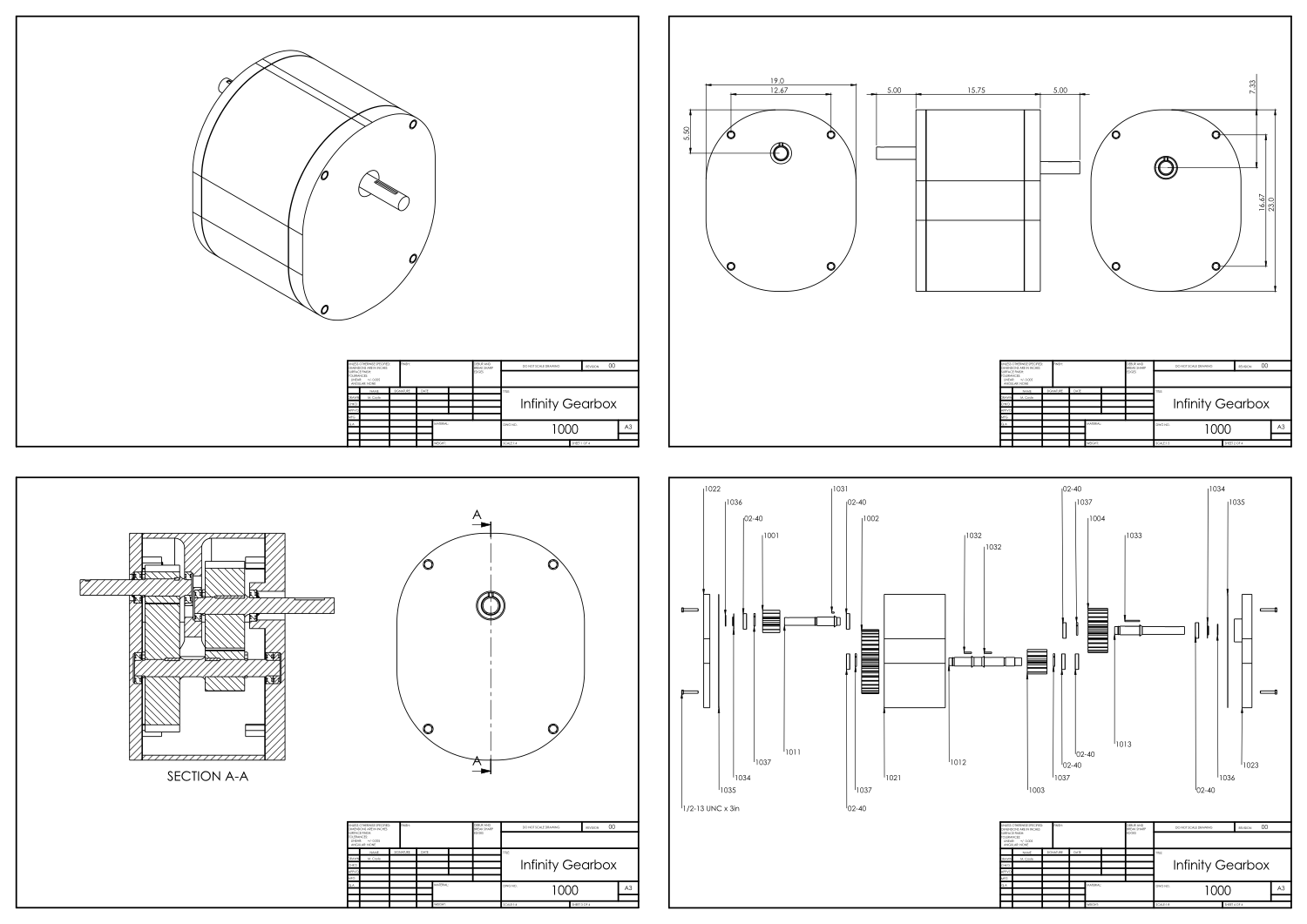

Enclosure and Assembly

Key enclosure features:

- Gearbox enclosure was designed to be concentric with the largest gear. This allows the minimum clearance to be used exactly without adding unnecessary space. It also helps to prevent buildup accumulating in sharp internal angles.

- Internal gears are accessible from both sides to aid in assembly and repairs.

- All enclosure components can be manufactured with simple two part molds.

- Cut-outs are provided behind internal bearings to allow them to be pushed from behind for easy removal.

- Only one type of bolt is used in all locations (UNC 1/2-13 x 3).